Technology

Building the Future: Digital Twins Revolutionize Construction

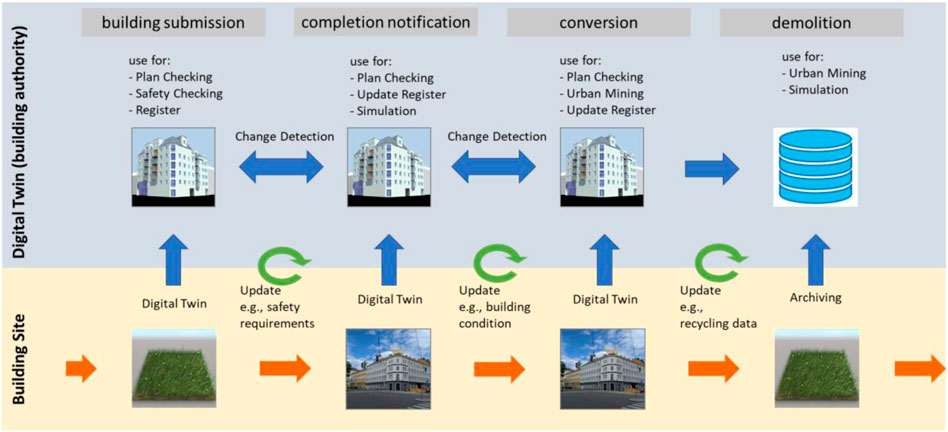

The construction industry, traditionally known for its reliance on static blueprints and physical models, is undergoing a digital transformation. At the forefront of this revolution lies the concept of digital twins. These digital replicas of physical buildings or infrastructure projects offer a dynamic and data-driven approach to construction, promising to improve efficiency, safety, and overall project outcomes.

Understanding Digital Twins in Construction:

A digital twin is a virtual representation of a physical asset, like a building, bridge, or even an entire city. In construction, digital twins are created by combining various data sources:

- 3D Models: Building Information Modeling (BIM) software creates 3D models containing detailed information about the building’s geometry, materials, and components. This forms the core of the digital twin.

- Sensor Data: Sensors embedded in building materials or construction sites can collect real-time data on temperature, humidity, pressure, and other environmental factors. This data helps monitor the construction process and predict potential issues.

- Operational Data: Once a building is constructed, data on energy consumption, occupancy levels, and equipment performance can be integrated into the digital twin, allowing for ongoing monitoring and optimization.

Real-Life Example: Constructing a Hospital with a Digital Twin

Skanska, a global construction and development company, used a digital twin approach to build a new hospital in Sweden. The digital twin integrated BIM models with real-time data from sensors on the construction site. This allowed for improved coordination between different trades, identified potential clashes between building components before construction, and facilitated better visualization of the finished building for stakeholders.

Benefits of Digital Twins in Construction:

Digital twins offer a multitude of advantages throughout the construction lifecycle:

- Improved Design and Planning: Digital twins allow for virtual prototyping and clash detection. This means potential issues with design or construction sequence can be identified and addressed virtually before construction begins, saving time and money.

- Enhanced Collaboration: A digital twin serves as a central platform for all project stakeholders, including architects, engineers, contractors, and owners. This fosters better communication and collaboration throughout the project lifecycle.

- Increased Efficiency: Digital twins can be used to optimize construction schedules, identify bottlenecks, and streamline logistics. This can lead to faster project completion times and reduced costs.

- Enhanced Safety: Real-time data from sensors can be used to monitor safety hazards on the construction site. For example, digital twins can be used to simulate evacuation procedures in case of emergencies.

- Improved Building Performance: Data collected from the digital twin after construction can be used to optimize building operations and maintenance. This can lead to reduced energy consumption, improved occupant comfort, and extended building lifespan.

Real-Life Example: Optimizing Energy Efficiency with a Digital Twin

The Dubai Electricity and Water Authority (DEWA) is using a digital twin of its headquarters building to optimize energy consumption. The digital twin integrates real-time data on energy use with weather data and building occupancy patterns. This allows DEWA to identify areas for improvement and implement energy-saving measures, such as adjusting lighting and HVAC systems based on real-time needs.

Challenges and Considerations for Digital Twins:

Despite their numerous benefits, digital twins also present some challenges:

- Data Integration and Management: Effectively integrating data from various sources and managing large datasets can be complex and requires robust IT infrastructure.

- Security Concerns: Digital twins house sensitive data about building design, materials, and operations. Robust cybersecurity measures are crucial to protect this data from cyberattacks.

- Cost and Expertise: Implementing digital twins requires upfront investment in technology and the expertise to manage and utilize the data effectively.

- Standardization and Interoperability: The construction industry lacks standardized data formats for digital twins. This can hinder collaboration between different software platforms and project stakeholders.

The Future of Digital Twins in Construction:

As technology advances and the construction industry embraces digitalization, we can expect exciting developments in the realm of digital twins:

- Integration with Artificial Intelligence (AI): AI can analyze data from digital twins to identify trends, predict potential problems, and recommend optimal solutions. This can revolutionize project management and decision-making.

- Augmented Reality (AR) and Virtual Reality (VR): AR and VR can be used to overlay the digital twin onto the physical construction site, allowing workers to visualize the finished building and identify potential issues before construction begins.

- Open-source platforms and standardized data formats: The development of open-source platforms and standardized data formats will facilitate collaboration and make digital twins more accessible to a wider range of construction projects.

Real-Life Example: Using VR for Construction Worker Training

Construction companies are increasingly using VR to train workers on complex tasks and safety procedures. By immersing workers in a virtual environment that replicates the construction site, VR can provide a safe and realistic training experience. Digital twins can be integrated with VR platforms, allowing workers to virtually interact with the building model and practice specific tasks in a safe and controlled environment.

Conclusion: Building a Brighter Future with Digital Twins

Digital twins represent a transformative force in the construction industry. By offering a data-driven and collaborative approach to building projects, they hold immense potential to improve efficiency, safety, and sustainability across the entire construction lifecycle. As we overcome the challenges, embrace technological advancements, and foster collaboration within the industry, digital twins can pave the way for a brighter future for construction – a future characterized by innovation, efficiency, and a commitment to building a better world.

Here are some additional thoughts to consider for your blog post:

- The Impact on Sustainability: Digital twins can play a crucial role in promoting sustainable construction practices. By simulating the energy performance of a building throughout its lifecycle, digital twins can help optimize design choices to minimize environmental impact and reduce energy consumption.

- The Evolving Role of Stakeholders: Digital twins empower all project stakeholders with greater access to information and a deeper understanding of the building project. This fosters a more collaborative and transparent environment, leading to better decision-making at every stage.

- The Future of Cities: Digital twins can be extended to encompass entire cityscapes, creating a “city digital twin.” This allows for better urban planning, infrastructure management, and resource optimization, leading to the development of smarter and more sustainable cities.