Technology

The Impact of 3D Printing on Manufacturing: From Prototyping to Production

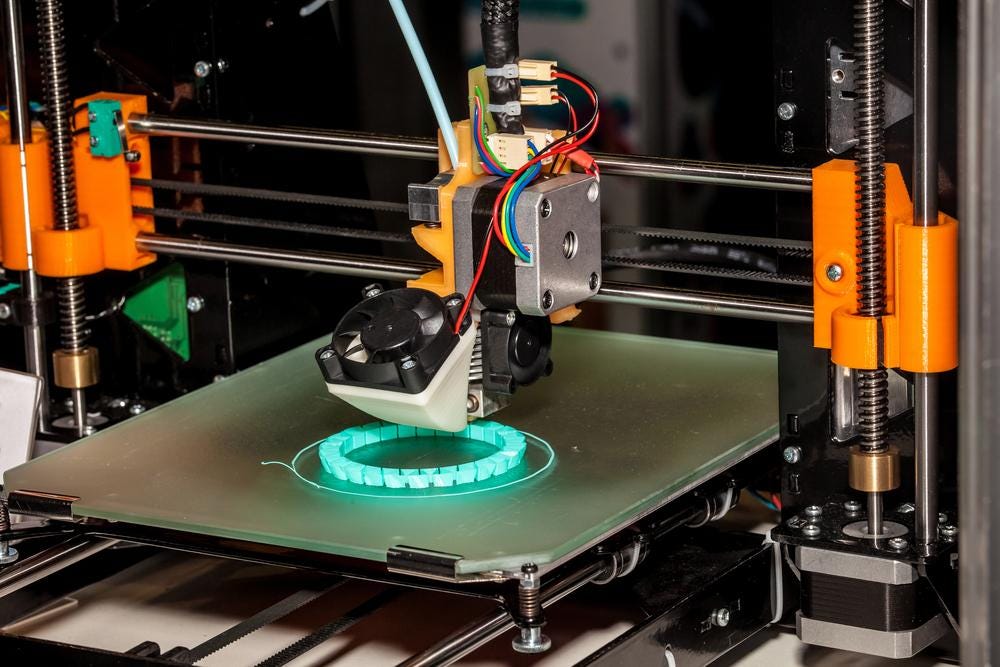

3D printing, also known as additive manufacturing, is a transformative technology rapidly reshaping the manufacturing landscape. Unlike traditional subtractive manufacturing methods that remove material to create an object, 3D printing builds objects layer by layer from a digital model. This blog post will delve into the impact of 3D printing on manufacturing, exploring its potential to revolutionize how products are designed, developed, and produced.

From Rapid Prototyping to Mass Customization: The Power of 3D Printing

3D printing offers several advantages over traditional manufacturing methods:

- Rapid Prototyping: 3D printing allows for rapid creation of prototypes, accelerating the design and development process. This enables faster iteration and product testing, leading to improved product quality and reduced time-to-market.

- Design Flexibility: 3D printing facilitates the creation of complex geometries and intricate designs that are difficult or impossible to achieve with traditional methods. This opens up new design possibilities for manufacturers.

- On-Demand Manufacturing: 3D printing enables localized, on-demand production, reducing the need for large production facilities and complex supply chains. This can be beneficial for customized products or low-volume production runs.

- Reduced Waste: 3D printing uses only the material needed to create the object, minimizing waste compared to traditional subtractive manufacturing methods.

Real-Life Example: 3D Printing in the Medical Field

3D printing is transforming the medical field by enabling the creation of customized prosthetics, implants, and even bioprinted organs and tissues. This technology holds immense potential for personalized medicine and improved patient outcomes.

The Future of Manufacturing: A Transformation in the Making

3D printing is poised to change the face of manufacturing in several ways:

- Distributed Manufacturing: 3D printing could lead to a shift from centralized manufacturing to distributed production, with products being printed closer to the point of use. This could reduce transportation costs and environmental impact.

- Mass Customization: 3D printing allows for the production of customized products at scale, catering to individual preferences and needs. This could revolutionize the retail industry and consumer experience.

- Supply Chain Transformation: 3D printing could disrupt traditional supply chains, with companies printing parts on-demand rather than relying on large inventories and complex logistics networks.

Challenges and Considerations:

- Scalability and Cost: While 3D printing is becoming more affordable, it may not be cost-effective for high-volume production compared to traditional methods. Scalability also remains a challenge for larger-scale applications.

- Material Limitations: The range of materials available for 3D printing is still limited compared to traditional manufacturing. However, advancements in material science are constantly expanding the possibilities.

- Standardization and Quality Control: Establishing standards for 3D printing materials and processes is crucial to ensure consistent quality and product performance.

The Road Ahead: Embracing Innovation for a Sustainable Future

3D printing presents a unique opportunity to revolutionize manufacturing, making it more flexible, efficient, and sustainable. By addressing the existing challenges and embracing innovation, we can unlock the full potential of 3D printing and build a more sustainable and responsive manufacturing landscape.

Real-Life Examples of 3D Printing in Action:

- Aerospace Industry: 3D printing is being used to create lightweight and high-strength components for airplanes and spacecraft, leading to improved fuel efficiency and performance.

- Automotive Industry: Automakers are increasingly using 3D printing to create prototypes, tooling, and even some end-use parts for vehicles. This allows for faster design iterations and customization options.

- Construction Industry: 3D printing is being explored for on-site construction of buildings and structures. This technology could revolutionize the construction industry by reducing waste, improving efficiency, and enabling the creation of complex architectural designs.

The Rise of Bioprinting:

A particularly exciting area of 3D printing is bioprinting, which uses biocompatible materials to create living tissues and organs. This technology holds immense potential for regenerative medicine, offering possibilities for:

- Skin grafts for burn victims

- Replacement of damaged organs

- Printing of complex tissues for drug testing

Bioprinting is still in its early stages, but it represents a significant leap forward in personalized medicine and has the potential to revolutionize healthcare.

The Future of Work: The Impact of 3D Printing on Jobs

The rise of 3D printing will undoubtedly impact the job market. While some jobs in traditional manufacturing may be automated, 3D printing will also create new opportunities in areas such as:

- 3D Printing Design and Engineering

- 3D Printing Material Science

- 3D Printing Operation and Maintenance

- Product Customization Specialists

The key will be to equip the workforce with the skills needed to thrive in this evolving manufacturing landscape.

Conclusion: A New Era of Manufacturing

3D printing is a transformative technology with the potential to reshape the way we design, develop, and produce goods. As the technology continues to evolve and become more affordable, we can expect to see even more innovative applications emerge. By embracing 3D printing and fostering a skilled workforce, we can build a more sustainable, efficient, and innovative manufacturing industry for the future.